XRF Technology

OUR XRF IS DESIGNED AND PROGRAMMED TO TEST ALL THE PRECIOUS METALS - GOLD, SILVER, PLATINUM AND ALSO THE ALLOYS USED TO MIX TO MAKE JEWELLERY LIKE COPPER, ZINC, PALLADIUM, ETC.

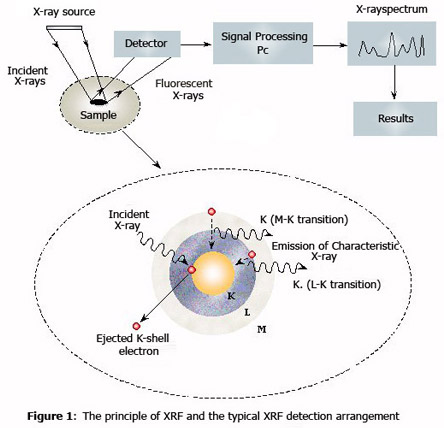

X-ray fluorescence spectroscopy (XRF) is universally recognized as a very accurate method of measuring the atomic composition of a material by irradiating a sample with high energy photons such as x-rays or gamma rays and observing the resulting x-ray fluorescence emitted by the sample.

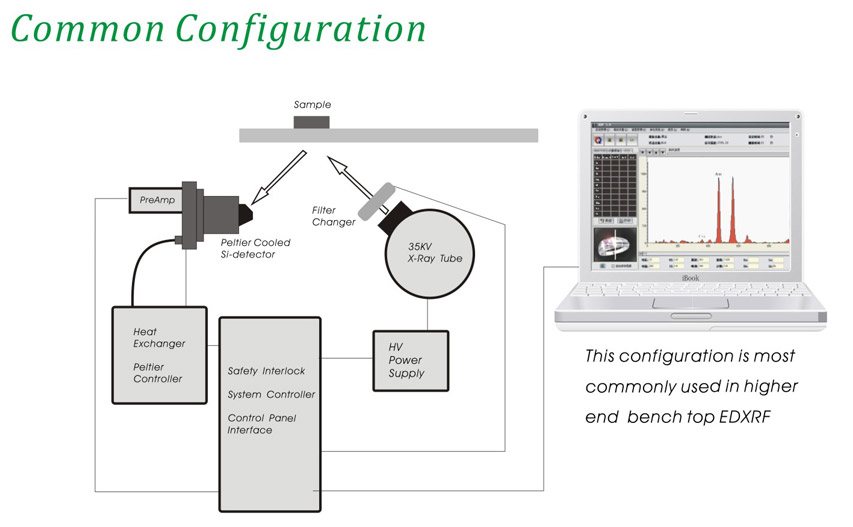

In general, x-ray fluorescence spectrometers consist of a source of excitation radiation (an x-ray tube or a radioisotope), a radiation detector to detect the stimulated radiation from the sample, and a display of the spectral output. Computers often are used to perform analysis of the data…

Configuration & Overview

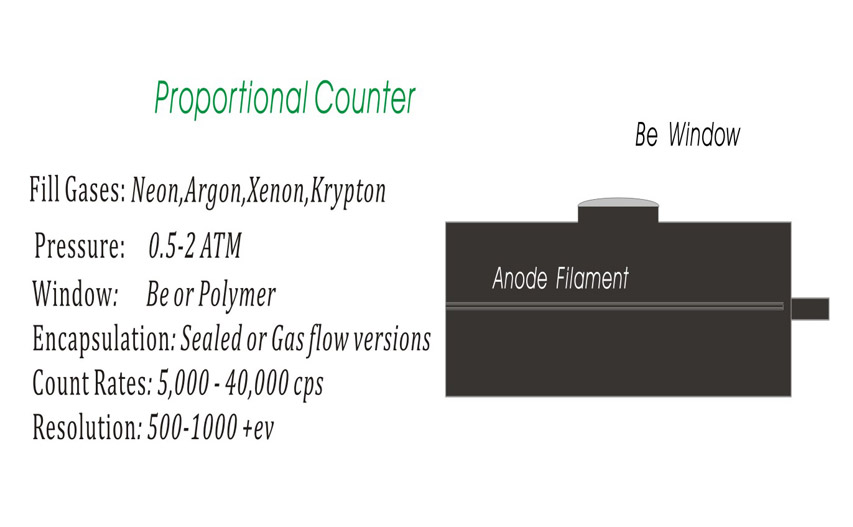

Gas Proportional Counter

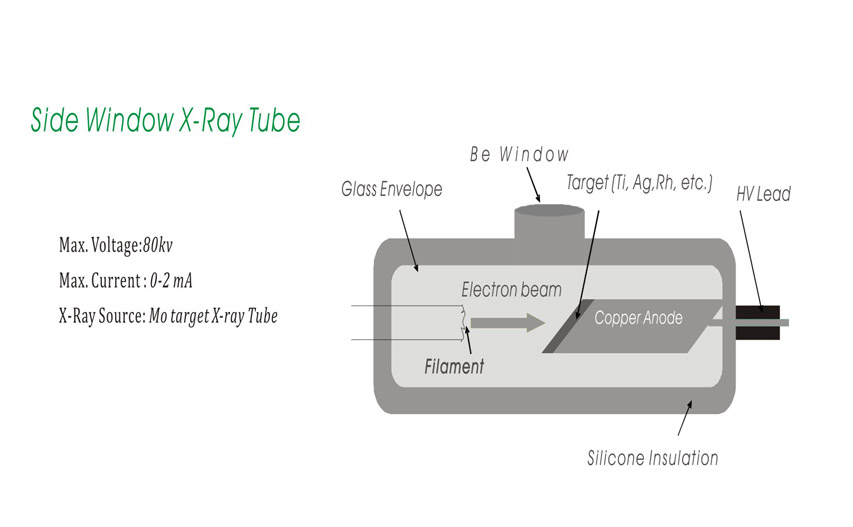

X-ray Tube Construction

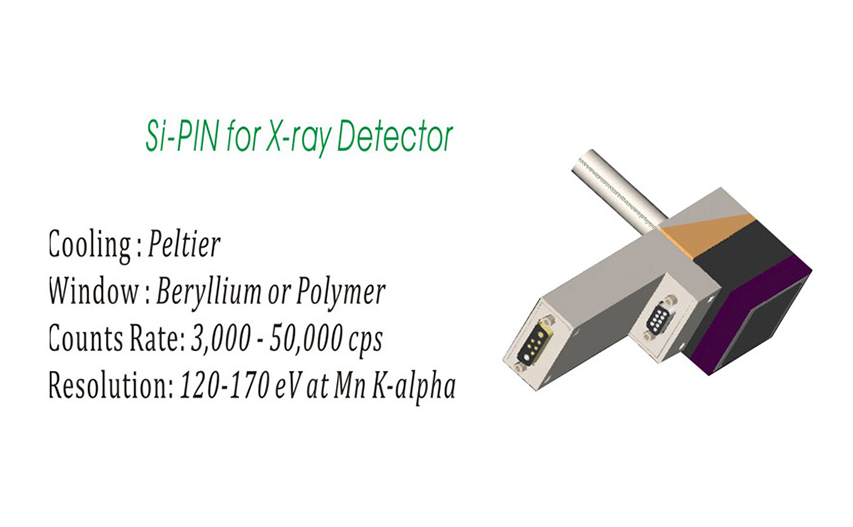

Si - Pin X-ray Detector

In X-ray fluorescence spectroscopy, the process begins by exposing the sample in question to a source of x-rays or gamma rays. As these high energy photons strike the sample, they tend to knock electrons out of their orbits around the nuclei of the atoms that make up the sample. When this occurs, an electron from an outer orbit or shell, of the atom will fall into the shell of the missing electron. Since outer shell electrons are more energetic than inner shell electrons, the relocated electron has an excess of energy that is expended as an x-ray fluorescence photon. This fluorescence is unique to the composition of the sample.

The detector collects this spectrum and converts them to electrical impulses that are proportional to the energies of the various x-rays in the sample spectrum. Since each element has a different and identifiable x-ray signature, we can look at specific parts of the emitted spectrum, and by counting the pulses in that sector, determine the presence and concentration of the element(s) in question within the sample.

Energy Dispersive X Ray Fluorescence (EDXRF) relies on the detector and detector electronics to resolve the spectral peaks which result when the X Ray is exposed on the Sample. The different energy levels construed from the exposure are detected by the XRF Detector and then they are processed by powerful analysis software. Thus the result is derived.

EDXRF is relatively simple and inexpensive when compared to other techniques. It requires X Ray Source, which is found in most laboratory instrument with a power of 50 – 60kV tube. The Next crucial component is X Ray detector, which is designed to convert the intensity of energy levels detected into electrical pulses. Normally proportional counters which is economical, reliable and accurate are used in Most XRF Analyzer of Precious Metal Analysis. However the modern Peltier cooled Silicon Pin Diode Detector is more powerful, but an expensive detector which determines fewer more elements.

XRF FOR GOLD AND PRECIOUS METAL

In the past decade, Gold has plunged year by year to new Highs due to its ease of liquidity and Globally acclaimed as Safest investment mode. As gold Prices have been rising, there is increased demand in need of analyzing the purity of Gold in any given sample. Both for the Jewellers and the Customers, Gold purity is a serious factor.

XRF Analyzers, which until the yester years were found in the R&D Centers and Labs for analyzing different elements, have found a New Line of Users. Gold Analyzing without the sample being Destructed is possible with XRF Technology. Its fast, Easy, Cost effective and reliable. XRF technology ensures that the Scientific way of testing the metal gives most accurate results with various Elemental and Quantitative analysis.

With the Indian govt. and most governments across the World, emphasizing on Hallmark Certification of Jewellery, the need for Gold Purity Analysis has increased. The BIS (Bureau Of Indian Standards) on various occasions have put forth the need for Jewellers to adhere to Hallmark Certified Jewellery sales. XRF Analyzer is one the instruments which has been identified as most ideal to test the Jewellery instantly.

Our XRF is designed and programmed to test All the Precious metals - Gold, Silver, Platinum and also the Alloys used to mix to make jewellery like Copper, Zinc, Palladium, etc.

Precious metal elements Such as Ag, Au, Pt, Rh, Ru, Pd, Cu, Zn, Ni, Co, etc., analysis can be achieved through XRF Spectrometer. During the manufacturing, retailing and recycling process of Gold and other precious metals, XRF helps in determining the loss and also establishing the quality standard of Jewellery.

Quality control is an integral part of Jewellery business, because as the prices are going higher, the curiosity of customer is high and critical in identifying or verifying the Gold purity of the Jewellery or the metal transacted. Moreover you need not melt, destruct or even damage the Jewellery to test. Everything is done at just a click of the mouse.

Various factors do determine the results of testing of Gold metal and Jewellery. One of them being the Use of Reference standards for Calibration, which should be in the most precise form.